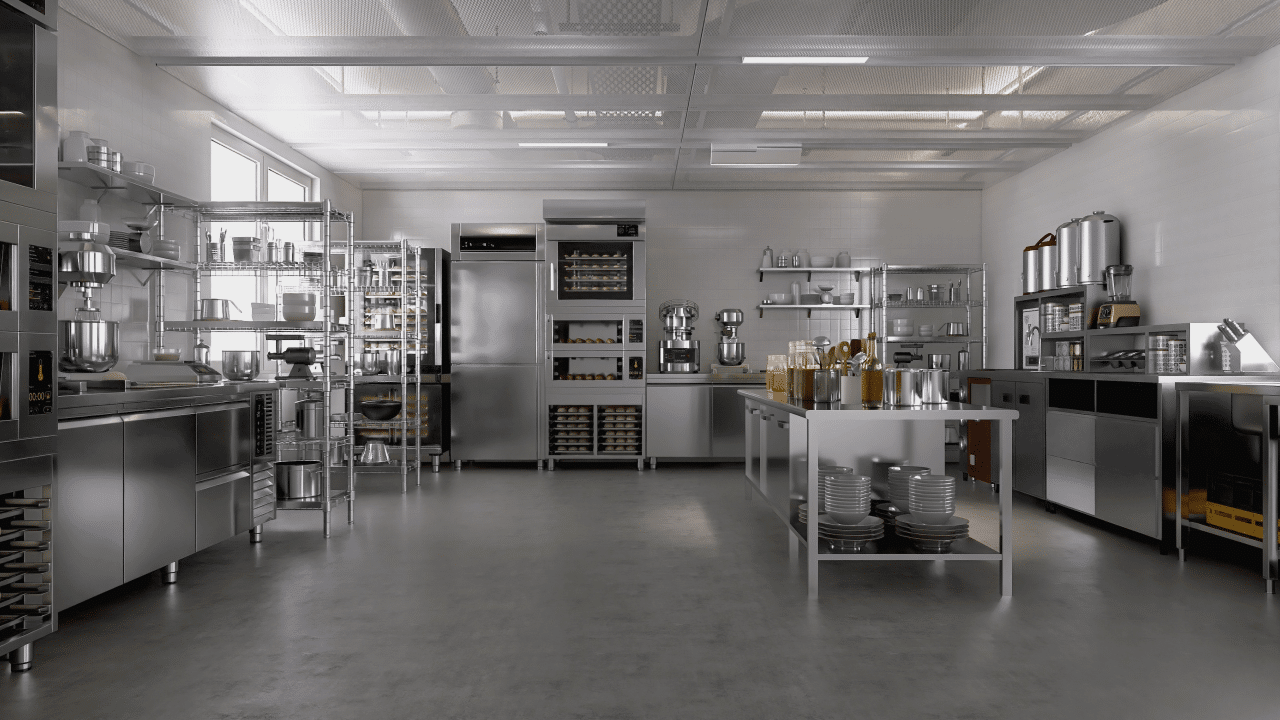

For operators of commercial kitchens, managing kitchen exhaust systems is crucial not only for efficient kitchen operation but also for minimising business risk and ensuring the safety of staff, customers, and property.

The recently released Best Practice Guide (BPG) for Commercial Kitchen Exhaust Management in Australia by the Australian Institute of Refrigeration, Air Conditioning, and Heating (AIRAH) offers a significant upgrade over the traditional AS 1851 standard, which has long guided exhaust system maintenance.

The need for a BPG in Australia for managing commercial kitchen exhaust systems arose from increasing awareness that traditional standards, like the Australian Standard AS 1851, provided baseline guidance for maintaining these systems but were not fully equipped to address evolving risks, advanced maintenance practices, or the specific challenges of different kitchen types.

The development of the BPG was considered essential for several reasons:

Continuing High Incidence of Kitchen Fires

There has been no reduction in the incidence of fires in commercial kitchens. Fire and Rescue New South Wales (FRNSW) reports that around one fire every week in New South Wales is linked to commercial kitchens, with many attributed to poorly maintained exhaust systems. Kitchens remain one of the primary sources of structural fires in commercial buildings. With the frequency of kitchen fires and associated losses in property and business, there was a clear need for a guide focused on fire prevention specific to kitchen exhaust systems.

Limitations of Existing Standards

AS 1851 provided a baseline but was limited by fixed maintenance intervals that did not account for variations in kitchen use or cooking types. The BPG introduced an evidence-based, risk-adjusted approach, allowing for customised maintenance schedules based on grease accumulation, type of cooking, and system usage. This tailored approach ensures that inspections and cleaning are done as needed, rather than adhering to potentially outdated or inadequate minimum standards.

Increased Complexity of Commercial Kitchens

Modern commercial kitchens have evolved to include a wider variety of cooking methods, from open flame grilling to wood-fired ovens, which produce different levels of grease and particulates. Additionally, the use of solid fuel and high-heat methods presents unique risks that standard guidelines may not adequately address. The BPG’s specific guidance on high-risk cooking methods, specialised equipment, and appropriate safety controls fills this gap.

Regulatory Compliance and Insurance Requirements

Insurance providers increasingly require detailed evidence of fire risk mitigation in commercial kitchens. The BPG aligns well with these demands, offering systematic processes for tracking and reporting maintenance activities, documenting grease levels, and conducting thorough inspections. This helps business owners not only comply with safety regulations but also demonstrates proactive risk management to insurers, potentially impacting premiums and claims.

Adoption of Global Best Practices

The BPG draws on standards from other countries with advanced kitchen exhaust management protocols, including the UK’s Building Engineering Services Association’s (BESA) TR19 Grease, in the USA NFPA96 and the International Kitchen Exhaust Cleaning Association’s (IKECA) guidelines. These international standards have successfully implemented risk-based approaches and comprehensive cleaning protocols, serving as a benchmark for Australia to follow.

By creating the BPG, Australia has effectively taken inspiration from these international standards while customising the guidelines to meet the unique needs of its commercial kitchen industry. This ensures that Australian venues are equipped with up-to-date, comprehensive standards to protect their kitchens from fire and health risks, in alignment with global best practices.

From Minimum Standards to Best Practice

For operators of commercial kitchens, managing exhaust systems is crucial not only for efficient kitchen operation but also for ensuring the safety of staff, customers, and property.

The Best Practice Guide (BPG) offers a significant upgrade over the traditional AS 1851 standard. For owners and managers of commercial kitchens, this guide is an essential tool that moves beyond the minimum standards to create a tailored, evidence-based approach to exhaust system maintenance, focusing on reducing fire risk and optimising performance.

Here are the standout improvements in the BPG that highlight why it’s an indispensable resource for the owners and operators of commercial kitchens.

Risk-Based Maintenance for Safety and Efficiency

AS 1851 has served as a foundational standard for maintaining kitchen exhaust systems, but it has certain limitations, primarily due to its fixed maintenance schedule. AS 1851 suggests that commercial kitchens maintain a set schedule for inspection, with limited flexibility to adjust based on the actual condition of the system.

In contrast, the BPG adopts a risk-based approach to inspection and cleaning, basing schedules on real-time grease thickness measurements and system usage. This ensures that inspection and cleaning are tied directly to how much grease builds up in each system, which varies based on the type of cooking, volume of cooking, and hours of operation. By aligning cleaning frequencies to grease accumulation, the BPG not only reduces fire risk but also allows managers to avoid unnecessary cleanings, providing a cost-effective and efficient maintenance strategy.

Enhanced Cleaning Protocols for Comprehensive Safety

One of the significant distinctions between the BPG and AS 1851 lies in their respective cleaning protocols. While AS 1851 offers general cleaning guidelines, the BPG goes several steps further, outlining detailed pre-cleaning inspections, protective measures, and specific cleaning methods designed to ensure thorough and safe cleaning processes.

The BPG recommends pre-cleaning inspections to identify potential system issues, allowing managers to address these before they escalate into costly repairs or safety hazards. Additionally, the BPG offers specific cleaning methods, such as wet-washing and grease filtration techniques, to achieve a thorough removal of accumulated grease and particulates that can compromise safety. For kitchen managers, these protocols offer a structured, dependable process for minimising fire risks associated with grease build-up.

Improved Access Requirements for Seamless Inspections and Maintenance

A common challenge in exhaust system maintenance is adequate access to ductwork and inspection points, often due to poor planning during installation. The BPG addresses this by setting rigorous standards for system accessibility, ensuring that every component can be inspected and cleaned efficiently.

BPG also promotes better coordination between contractors to prevent obstructed access points — a recurring issue where other services, like fire sprinklers or electrical wiring, block necessary duct access panels. For managers, the guide’s focus on easy access translates to smoother, faster inspections and fewer disruptions to daily kitchen operations.

Grease Thickness Standards for Proactive Risk Management

Traditional AS 1851 standards do not provide specific guidelines for measuring grease accumulation within exhaust systems, leaving much to general assessment. The BPG, however, introduces clear grease thickness limits as markers for cleaning, which provides a proactive approach to maintenance. For instance, the BPG suggests a maximum mean grease thickness of 0.2 mm for general ductwork and a threshold of 2.0 mm for urgent cleaning in specific areas. These precise standards allow kitchen managers to implement maintenance only when necessary, minimising disruptions to kitchen operations while keeping fire hazards in check.

With such tangible metrics in place, operators can better communicate the importance of regular exhaust cleaning to stakeholders, including insurance providers, demonstrating a proactive approach to risk management.

Competency and Training Standards for Maintenance Personnel

Beyond just the systems themselves, the BPG raises the bar for personnel involved in exhaust maintenance. Where AS 1851 presumes general competency, the BPG emphasises comprehensive training in risk management, inspection protocols, and cleaning techniques. Maintenance personnel are trained specifically on fire risk factors and the hazards of grease accumulation, enhancing their ability to detect and mitigate safety risks.

For kitchen managers, this focus on staff competency provides an added layer of confidence. Knowing that inspections and cleanings are performed by personnel who understand the unique requirements of commercial kitchen exhaust systems helps safeguard the business and its people.

A Practical Guide to Enhanced Compliance and Safety

In summary, the BPG represents a valuable evolution from the AS 1851 standard, updating kitchen exhaust maintenance practices to align with modern safety expectations and efficiency demands. The guide’s focus on accessibility, evidence-based maintenance, and robust cleaning protocols establishes a new benchmark in the industry, offering a proactive approach to managing fire and health risks associated with commercial kitchen exhaust systems.

For owners and operators of commercial kitchens, adopting these best practices will not only enhance compliance but also reduce potential fire hazards and improve operational efficiency. By embracing the BPG’s standards, kitchen managers can demonstrate a commitment to safety that goes above and beyond, providing safer kitchens and peace of mind for everyone involved.